Most people look at a horse menage and see a nice, finished equestrian surface on which to work their horses. However, they do not know what lies below; what is actually keeping the horse arena in good condition in all weathers for many years. If you get the basics of the construction wrong you stand the chance of flooding and freezing etc. Good preparation is always the key to success.

Making the Formation Level

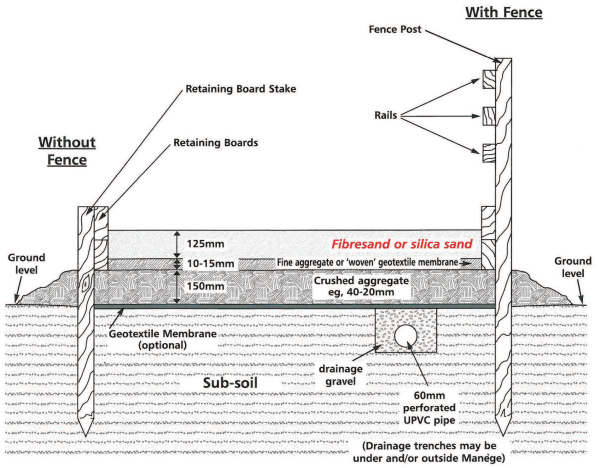

The total thickness of a horse menage should be between 350 and 400mm thick, depending on your choice of top finish. It is not a good idea to build straight onto the current topsoil as this holds a lot of organic matter that blocks the drainage. It has to be removed. But don’t dispose of the soil as it can be used to regulate the outside of the finished arena or to fill in lying areas to spread grass seeds. Try to avoid sending items to the tip as this can be rather expensive. After removing the topsoil you need to get the formation quite flat. This may result in excavating some places and filling others. Once this level is complete you can start the proper building of the horse arena.

Below Ground Drainage

Drainage is a key part of the dressage arena. The arena needs to be functional during the whole year and not suffer from harsh weather. This means it needs to drain well. The most common method is called the Herringbone Pattern. This incorporates the main carrier drain down the centre with other drain pipes branching off to the side of the horse arena. The other drains run across the arena from one side to the other. Any drainage system you use will follow the same principle of collecting drains feeding into the carrier. The carrier drain then feeds into the main drain run like a ditch or stream. The drains need to be perforated or slotted to allow water to drain into them. We advise using Channel Drain.

Aggregate Layer

Once the drainage layer is complete, cover with a Woven Membrane to strengthen and stop your layers from mixing up. This is often called the base layer. The next stage for your horse arena is to add an aggregate that allows for slight compacting but still lets water pass through to the drains. Many natural materials can be used for this, such as granite, slate, flint, limestone and sandstone. Just make sure they are free from clay, coal and sand. Recycled aggregates are also fine for the arena, like crushed concrete or brick, as long as there is no wood or plastic. It is not advised to use a bituminous product as over time these can block water passing through. The ideal sub-base material will be from 25 to 75mm with no fines. This allows water to pass through quickly, but fines will force through and can block the drains. For a common 20m x 40m horse arena we advise a layer thickness of about 100mm. On top of the aggregate, you need a Non-Woven Geotextile Membrane, also called Fleece Membrane. This separates the layers, allows water to pass through and makes the horse arena more stable.

Top Finish

Once the drainage layer is complete, cover with a Woven Membrane to strengthen and stop your layers from mixing up. This is often called the base layer. The next stage for your horse arena is to add an aggregate that allows for slight compacting but still lets water pass through to the drains. Many natural materials can be used for this, such as granite, slate, flint, limestone and sandstone. Just make sure they are free from clay, coal and sand. Recycled aggregates are also fine for the arena, like crushed concrete or brick, as long as there is no wood or plastic. It is not advised to use a bituminous product as over time these can block water passing through. The ideal sub-base material will be from 25 to 75mm with no fines. This allows water to pass through quickly, but fines will force through and can block the drains. For a common 20m x 40m horse arena we advise a layer thickness of about 100mm. On top of the aggregate, you need a Non-Woven Geotextile Membrane, also called Fleece Membrane. This separates the layers, allows water to pass through and makes the horse arena more stable.